Laser repair techniques have transformed various industries, making it possible to achieve effective results in restoring materials. Dr. Emily Carter, a leading expert in the field, states, "Precision matters in laser repair; it's about knowing when and where to apply the technique." This insight emphasizes the delicate balance between skill and technology.

In recent years, the demand for laser repair services has surged. Industries such as automotive, aerospace, and even electronics rely heavily on these methods. However, many professionals struggle with the learning curve. Mistakes can happen, and the margin for error is slim. Understanding how to wield laser technology effectively is crucial for quality outcomes.

As laser repair continues to evolve, ongoing education is vital. Practitioners need to reflect on their techniques and outcomes. While the results can be remarkable, the path to mastery is filled with challenges. Each project serves as a learning opportunity, showing the importance of precision and practice in laser repair.

Laser repair techniques have transformed various industries, offering precise and efficient solutions. These methods leverage the power of concentrated light to repair materials ranging from metals to polymers. A report by the International Laser Association indicated that the laser repair market is expected to grow by 25% annually. This rapid growth highlights the increasing acceptance of laser technology in repair applications.

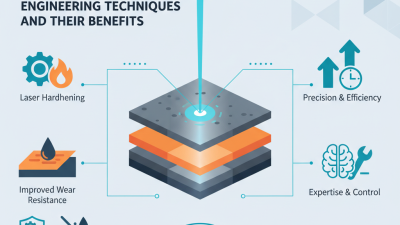

Common techniques include laser welding, laser hardening, and laser cladding. Each method has unique benefits depending on the material and type of damage. For example, laser welding offers strong joints with minimal heat distortion. On the other hand, laser cladding is ideal for restoring worn surfaces. Users often overlook surface preparation, which is critical for successful repairs. Proper cleaning and surface treatment can significantly enhance the outcome.

Tips: Always perform a test run on scrap material. This helps to confirm settings before proceeding with actual repairs. Remember, not every defect can be perfectly repaired. Assess the extent of damage carefully. Sometimes a complete replacement might be more effective than endless fixes. Adjusting expectations is essential for effective outcomes in laser repairs.

When selecting the right laser equipment for repair processes, several factors come into play. Laser technology is evolving rapidly, which means the options can be overwhelming. Reports suggest that over 60% of organizations face challenges in choosing the appropriate equipment due to varying needs and specifications. It’s crucial to match the laser type to the materials being repaired. For instance, fiber lasers perform exceptionally well on metals, while CO2 lasers are preferred for plastics and wood.

Tips: Consider compatibility with the materials you frequently work with. This simple step can save time and increase efficiency.

Another key consideration is the laser's power output and wavelength. Research indicates that the optimal power for most repair applications ranges from 20 watts to 100 watts. Choosing equipment that exceeds requirements can lead to excessive heat and damage. Also, assess the accuracy and precision of the laser. Inaccurate settings can compromise repair quality, leading to rework.

Tips: Always test settings on scrap materials before proceeding with your actual project. This will help you avoid costly mistakes.

Calibration and maintenance are often overlooked aspects of laser equipment. Regular checks ensure that you maintain optimal performance levels. Neglecting these can result in reduced efficiency and quality over time, which is not ideal for any repair operation.

| Laser Type | Wavelength (nm) | Power (W) | Material Compatibility | Typical Applications |

|---|---|---|---|---|

| CO2 Laser | 10,600 | 50-100 | Wood, Plastic, Glass | Cutting, Engraving |

| Fiber Laser | 1,064 | 100-600 | Metal, Aluminum, Steel | Welding, Cutting, Marking |

| Nd:YAG Laser | 1,064 | 20-500 | Metals, Glass, Ceramics | Repair, Marking, Engraving |

| Diode Laser | 700-980 | 5-30 | Plastic, Textiles | Engraving, Cutting |

| UV Laser | 355 | 1-20 | Glass, Ceramics, Plastics | Marking, Fine Cutting |

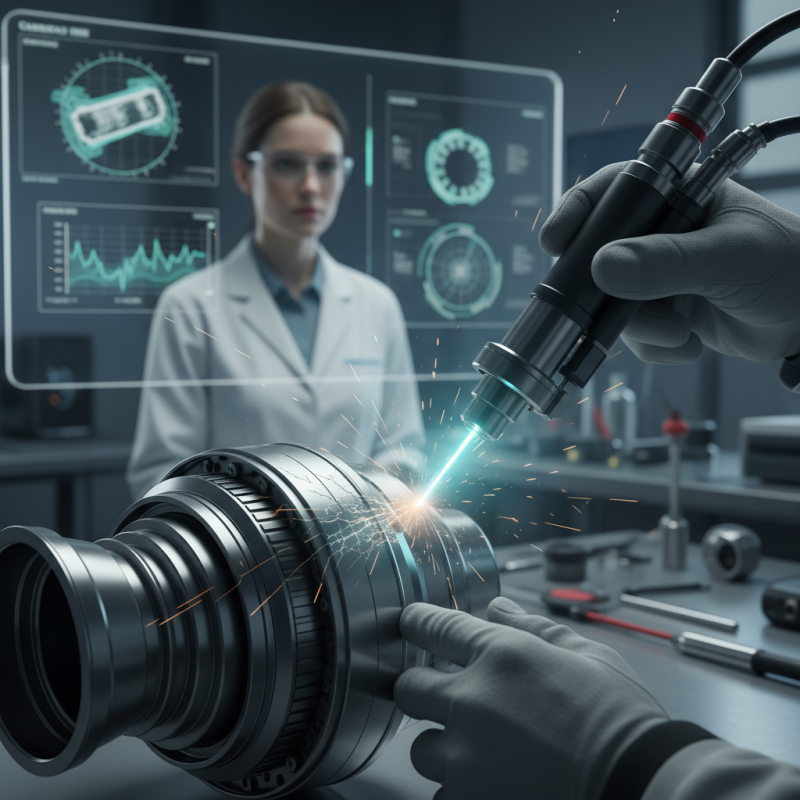

Performing laser repairs can seem daunting, but a clear step-by-step process can clarify this technique. Begin by preparing the workspace. Ensure proper lighting and cleanliness. Gather all necessary tools, such as safety glasses and the laser device. This preparation is critical. Without it, the outcome may suffer.

Next, assess the surface needing repair. Inspect for damage closely. Mark areas that require attention. This step can be overlooked but is essential. Applying the laser requires precision. Adjust the settings based on the material type and damage level. Improper settings can lead to less than optimal results. Each repair process needs careful monitoring.

During operation, consistent movement is key. Slow and steady helps achieve even results. Many make the mistake of rushing. Patience is crucial. After treatment, observe the results closely. Look for any imperfections. Reflecting on each step can improve future performances. It's a learning process, after all. Embrace the challenges and refine your technique over time.

When performing laser repair procedures, safety comes first. Adhering to safety protocols is essential to protect both technicians and clients. A recent report from the Laser Institute states that 30% of accidents occur due to improper safety measures. Therefore, establishing a solid framework for safety is critical.

Wear protective eyewear to shield against harmful laser light. Ensure that all equipment is well-maintained and frequently inspected. Creating a controlled environment helps minimize risks. Clear the area of non-essential personnel. This simple step can significantly lower the chance of accidents.

Tip: Always keep fire extinguishing equipment nearby.

In addition, proper training for all staff members is imperative. A study revealed that trained technicians complete procedures with 25% fewer errors. Regular drills and refresher courses can build confidence and reinforce best practices. Document all repair procedures. This not only enhances accountability but also serves as a reference for future repairs.

Tip: Create a checklist before each procedure.

While laser repair techniques can be effective, they aren’t without challenges. Technicians may encounter unforeseen complications requiring quick thinking. Having a solid safety plan can help them navigate these situations. Keeping lines of communication open among team members is vital during repairs.

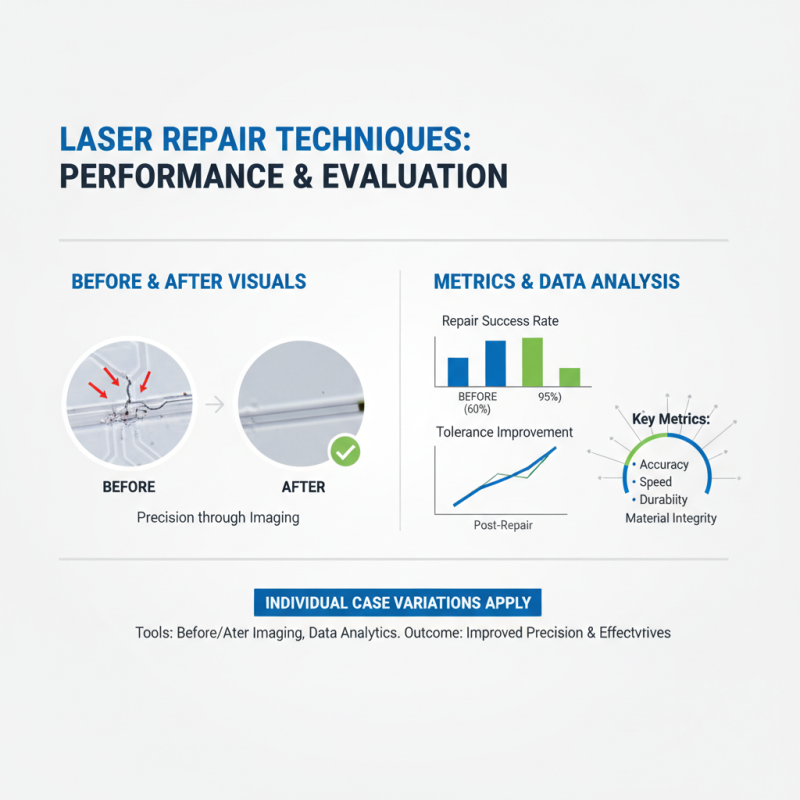

Laser repair techniques have gained popularity due to their precision and effectiveness. Evaluating their performance requires a solid understanding of metrics and data analysis. Tools such as before-and-after imaging are crucial. They provide clear visual evidence of the repair outcome. However, metrics alone can't capture the entire picture. Some results may vary based on individual cases.

Data analysis involves both quantitative and qualitative assessments. Collecting numerical data on recovery time and success rates is essential. Yet, it’s equally important to gather feedback from patients or clients. Their experiences often reveal insights that numbers cannot show. Moreover, inconsistencies in results need to be addressed. Anomalies can arise for various reasons, including skin type or environmental factors.

Through proper evaluation, practitioners can refine their techniques. This reflection allows for adapting methods to improve outcomes. Sometimes, failure to meet expectations occurs, prompting a re-examination of the approach. Each attempt provides a fundamental learning opportunity, pushing the boundaries of what is possible in laser repair. By balancing metrics with human experience, the effectiveness of laser repair can be enhanced considerably.