Choosing the right Laser Cladding Powder is crucial for successful projects. This decision can affect performance, durability, and costs. Experts emphasize the importance of selecting high-quality materials. Dr. John Smith, a renowned specialist in laser technologies, stated, "The right powder can make the difference between success and failure in cladding applications."

When navigating the options, consider the specific requirements of your project. Different powders yield varying results, impacting the final product's properties. For instance, certain powders may enhance wear resistance, while others focus on corrosion. This variety can make decisions overwhelming. Not every choice will suit your needs perfectly.

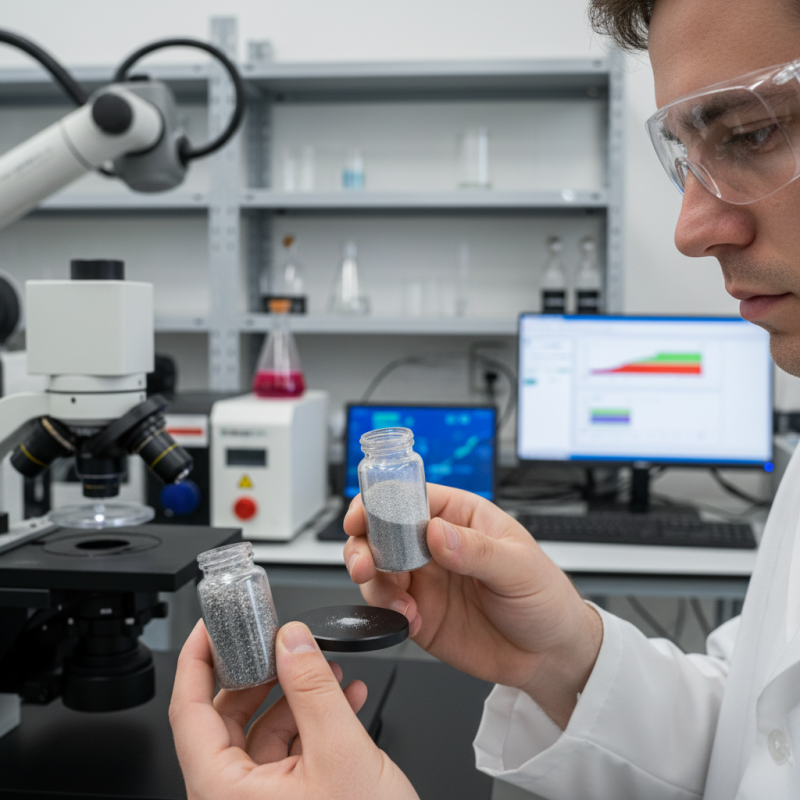

It's essential to evaluate factors like particle size and chemistry. Sometimes, it’s hard to find the ideal match. You may need to test several powders before settling on one. Remember that the best option isn't always the most popular. Careful research and testing are vital, as the consequences of a wrong choice can be significant.

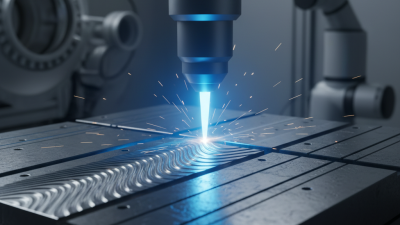

Laser cladding is an advanced process used for coating materials. It involves melting a powder with a laser to create a strong bond with the substrate. This method is efficient and can be tailored for various industries, including aerospace, automotive, and energy. According to recent industry reports, the global laser cladding market is expected to reach $600 million by 2025, growing at a CAGR of 7% from 2021. This growth showcases the increasing demand for high-performance materials.

The benefits of laser cladding are significant. It enhances the surface properties of components, increasing wear resistance and corrosion resistance. For example, cladding can improve the lifespan of turbine blades, which are often exposed to extreme conditions. A study found that laser-clad components can last up to 50% longer than their uncoated counterparts. However, it's important to choose the right powder for optimal results. Various compositions exist, including nickel-based and cobalt-based powders, each with unique characteristics.

Choosing the wrong powder can lead to performance issues or poor adhesion. Some materials may not bond well, affecting longevity. Users should analyze their specific application needs carefully. Newer technologies are emerging, but challenges remain. Understanding the complexities of material interactions is crucial. The right powder selection is key to maximizing the benefits of laser cladding.

Choosing the right laser cladding powder is crucial for project success. Several key factors can significantly impact the final results. Material composition is one of these factors. For instance, alloying elements can influence hardness and wear resistance. A recent report from the Laser Institute of America emphasizes that the right composition can improve tool life by up to 30%.

Another essential consideration is powder size. The particle size distribution affects the flowability and packing density. Research shows that finer powders can lead to better density and fewer defects. However, very fine powders may be harder to handle. A balance is necessary.

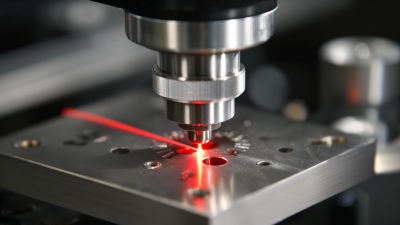

Additionally, the application method matters. Different techniques like DED or SLM have unique requirements. Understanding these can guide the choice of powder. Each technique may yield varying bond strengths and mechanical properties. This is an area for reflection. Does the project align with the advantages offered by a specific cladding powder? Selecting the wrong one can result in inefficiencies.

When selecting the right laser cladding powder, understanding the different types is essential. There are several materials used for cladding, each with unique properties and applications. Common materials include stainless steel, cobalt chrome, and tungsten carbide. Stainless steel is often chosen for its corrosion resistance and strength. Cobalt chrome offers excellent wear resistance and is ideal for high-performance applications. Tungsten carbide is known for its durability and hardness, suitable for severe wear conditions.

Tips: Identify the application before choosing the powder. Consider factors like temperature, wear conditions, and desired hardness. This will help in selecting the right material.

Another factor to consider is the particle size of the powder. Finer powders can provide better surface finish and help achieve a smoother layer. However, they may not be suitable for every project. Larger particles can enhance deposition rates but may lead to rough surfaces. Balancing particle size and application requirements is crucial.

Continuous feedback is key in the selection process. Test various powders and evaluate their performance. This iterative approach can reveal insights that initial research may not cover. Always review the results critically to make informed decisions for future projects.

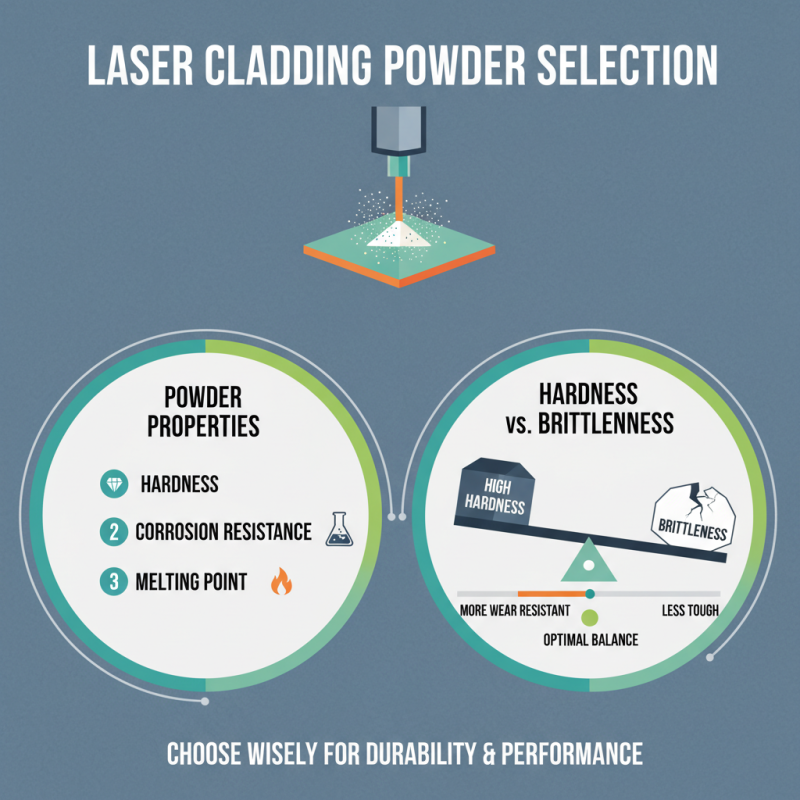

Choosing the right laser cladding powder can significantly affect the outcome of your projects. Evaluating powder properties is crucial. Hardness is one key factor. Harder powders tend to wear better over time. However, excessive hardness can lead to brittleness. Finding a balance is important.

Composition plays a substantial role as well. Different alloys offer varying benefits. Some can enhance corrosion resistance, while others improve strength. It’s essential to know the environment your coating will face. Will it endure high temperatures or corrosive materials?

Melt behavior affects the coating process. Powders with good flowability ensure even distribution. If the powder clumps, the application will not be uniform. Testing the melt behavior in lab conditions can save time. Poor melt properties may lead to defects. Reflect on the properties that best suit your project needs. Each choice impacts the final quality of the clad layer.

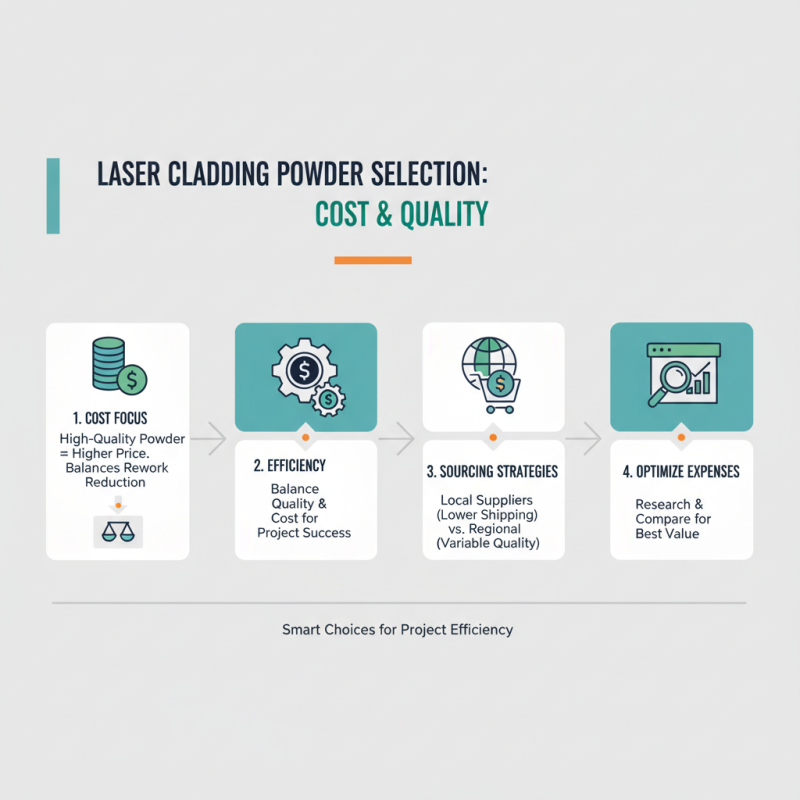

When selecting laser cladding powder, cost should be a key focus. High-quality powder often comes with a higher price tag, but it can reduce the need for rework. Balancing quality and cost is important for project efficiency. Sourcing strategies play a critical role in managing expenses. Consider local suppliers to minimize shipping costs. However, regional suppliers may not always offer the best quality.

Tips: Always request samples before making a bulk purchase. Testing the powder can save costs in the long run. Additionally, keep an eye on the market for price fluctuations. It’s essential to stay informed about trends in laser cladding materials.

Avoid relying solely on online suppliers. Establish relationships with trusted vendors. Building rapport can lead to better deals and exclusive offers. It’s also wise to evaluate the overall supply chain. Unexpected delays can increase expenses significantly. Regularly reviewing your sourcing strategy can reveal opportunities for improvement.