Choosing the right laser head is crucial for your engraving projects. A suitable laser head can enhance precision and efficiency. However, with various options available, making this choice can be overwhelming.

Different materials require different laser heads. For wood, a standard head might suffice. But for glass, a specialized head is often necessary. Think about the details of your project. The intricacies of your design can determine the type of laser head you need. It's essential to consider the power and speed required for your engravings.

Evaluate your budget, too. High-quality laser heads can be expensive. Yet, investing in the right one can yield better results. Remember, your choice affects the final product's quality. Reflect on past projects and think about what could have been done better. A little consideration can go a long way in achieving the desired outcome. Select wisely, as the right laser head can transform your engraving experience.

Laser engraving technology has become a powerful tool for artists and manufacturers alike. Understanding its core principles is essential for successful projects. At its heart, this technology utilizes a laser beam to etch designs into various materials. The precision and detail achieved can be remarkable. However, matching the right laser head to your project is crucial.

Different laser heads excel in specific applications. For instance, some are better for soft materials like wood, while others handle metal efficiently. It's important to consider power levels, focusing capabilities, and cooling mechanisms. Yet, many users overlook these details. They may assume that any laser head will suffice. This can lead to frustration and failed projects.

Moreover, the learning curve can be steep. Setting up a laser engraving machine often involves trial and error. Users must calibrate their settings based on material type and project complexity. This process can feel daunting at first. But, it’s vital to embrace the challenges. Each mistake becomes a lesson that sharpens your skills. Ultimately, understanding the basics of laser engraving allows for more creativity and success in your projects.

| Laser Head Type | Power (W) | Max Speed (mm/s) | Material Compatibility | Recommended Uses |

|---|---|---|---|---|

| CO2 Laser Head | 40-150 | 1000 | Wood, Acrylic, Leather | Engraving and Cutting |

| Fiber Laser Head | 20-100 | 1200 | Metal, Anodized Aluminum | Marking and Engraving |

| Diode Laser Head | 1-10 | 300 | Wood, Paper, Cardboard | Engraving Small Items |

| UV Laser Head | 5-50 | 500 | Glass, Plastic | High-Precision Marking |

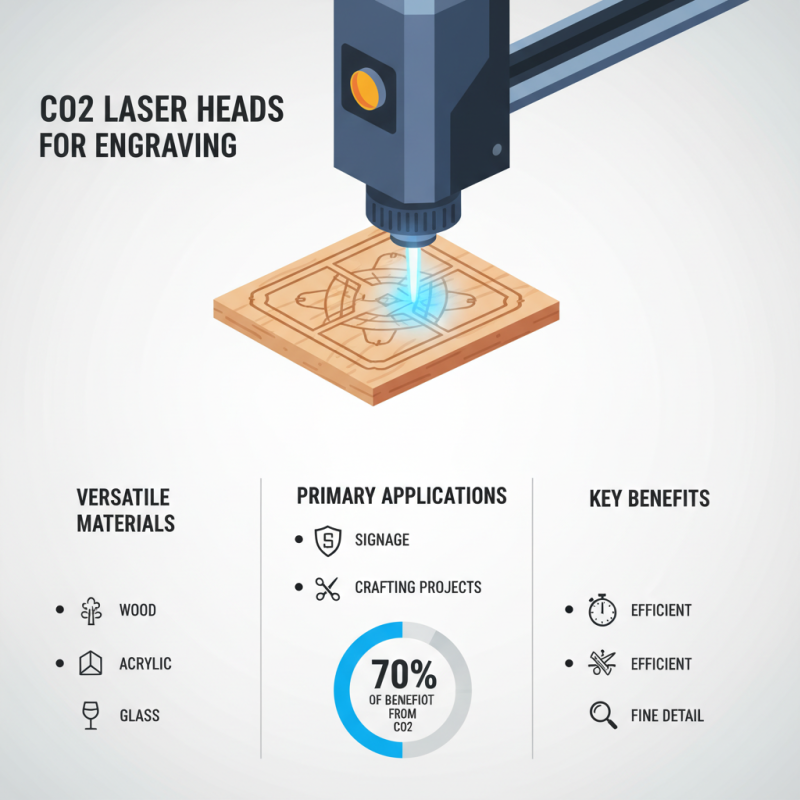

Choosing the right laser head for engraving requires understanding different types and their applications. CO2 laser heads are among the most commonly used. They work well with materials like wood, acrylic, and glass. Reports indicate that about 70% of signage and crafting projects benefit from CO2 technology. It’s efficient and delivers fine detail.

Fiber laser heads offer a different set of advantages. They excel at engraving metals such as aluminum and stainless steel. Research shows that they can achieve engraving speeds up to 10 times faster than CO2 lasers on metal. However, they are not suitable for softer materials. This limitation can be frustrating for users handling various substrates.

Diode lasers represent another option. They are less powerful but are cost-effective for hobbyists. While ideal for beginners, their engraving quality on harder materials may lack the finesse that professionals require. Some users may find themselves reflecting on their needs after an unsatisfactory finish. It’s essential to assess the type of materials and intricacies involved in your projects when selecting the right laser head.

When selecting a laser head for engraving projects, several factors play a crucial role. The type of material you plan to work with influences the choice significantly. For example, softer materials like wood require different head specifications compared to metal. A report from the Laser Institute of America indicates that precision and power settings differ across various applications.

Tip: Always consider the thickness of your material. Thicker materials demand a laser head that can maintain consistent power and precise focus.

Another factor to consider is the speed of engraving. Faster speeds can reduce engraving time, but may compromise detail. Data suggests that slower speeds often yield cleaner and more intricate designs. Balancing speed and detail is critical, and finding the right laser head can help achieve both.

Tip: Test your laser head on scrap material before starting your main project. This can provide insights into the compatibility of the head with your chosen materials. Remember, not all heads perform equally well across different projects. It's essential to reflect on your experiences and adjust your approach based on results.

This chart illustrates key factors to consider when selecting a laser head for engraving, focusing on power, speed, material compatibility, and cost:

When selecting a laser head for your engraving projects, specifications play a crucial role. The focus lens diameter, for instance, affects beam width. A smaller lens means finer details but may limit the cutting thickness. Pay attention to the wattage too. Higher wattage generally means faster engraving speeds and the ability to handle denser materials.

Tips: Always consider what material you'll be engraving. Some lasers handle wood exceptionally well, but struggle with acrylic. Test different configurations. It’s often helpful to experiment with settings before committing to a full project.

Don’t ignore the cooling system of the laser head. An efficient cooling system prevents overheating and prolongs the life of your equipment. However, more complex cooling can lead to higher maintenance. Reflect on your capabilities and resources when making a choice.

Keep an eye on the focus adjustment range. Too narrow a range limits versatility. Conversely, a wide range may be overwhelming and complicated. Understand your engraving needs to find the best balance. Seeking advice from users with similar projects can also provide valuable insights.

Proper maintenance of your laser engraving head is essential for optimal performance. The engraver's head can wear down over time. Regular checks can help catch potential issues early. Data suggests that around 30% of laser malfunction stems from neglect in maintenance. Therefore, cleaning your laser lens and mirrors at least once a week is crucial. Use a microfiber cloth and a gentle cleaning solution to avoid scratches.

Temperature control is another vital aspect. Ideally, the laser head should operate within specific temperature limits. Overheating can lead to reduced engraving quality and damage. Reports indicate that overheating can decrease engraving head lifespan by up to 50%. A simple temperature monitoring system can provide timely alerts to avoid this issue.

Sometimes, users overlook the importance of alignment. Misalignment may not show immediate effects but can lead to inconsistent engraving quality. It is advisable to recalibrate the head after every major session. This small step saves time and resources in the long run, enhancing the overall quality of work while extending equipment life. Regular maintenance might seem tedious, but it pays off in durability and performance.