Laser Surface Treatment (LST) is transforming the materials industry with its precision and efficiency. According to a report by MarketsandMarkets, the global laser processing market is projected to surpass $14 billion by 2027, showcasing significant growth potential. This method enhances surface properties including wear resistance, corrosion resistance, and aesthetic appeal.

Dr. Emily Hart, an expert in laser technologies, states, "Laser Surface Treatment offers remarkable improvements in material longevity." Industries such as aerospace and automotive are rapidly adopting LST for its superior results. Despite its benefits, there are challenges. The initial setup costs can be high. Not all materials respond equally well to LST.

This cutting-edge process is not without its complexities. The knowledge gap remains a barrier for some manufacturers. Continuous research is essential for technological advancements. As businesses embrace LST, they must weigh the benefits against these hurdles. Balancing innovation with practicality is key to leveraging the full potential of Laser Surface Treatment.

Laser surface treatment is a cutting-edge technology used to enhance the properties of materials. This technique employs focused laser beams to alter the surface characteristics of metals or polymers. The treatment can improve hardness, wear resistance, and corrosion resistance, making it an ideal choice for various applications.

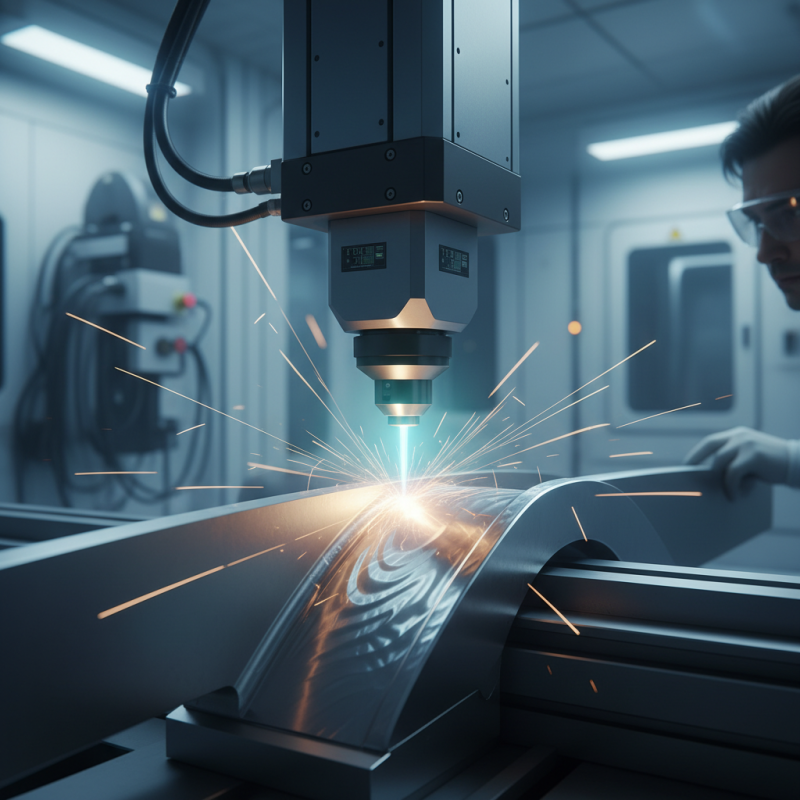

During the process, different laser parameters can be adjusted. These include power, speed, and focal length. By precisely controlling these factors, different effects can be achieved. However, achieving the perfect setting can be challenging. Sometimes, the results may not meet expectations, leading to further adjustments.

One interesting aspect is the versatility of laser treatment. It can be applied to a wide range of materials. However, not all materials respond well. Certain polymers might warp or degrade under laser exposure. This unpredictability can be frustrating but also presents opportunities for innovation. Exploring these boundaries is crucial for advancing the technology further.

This bar chart illustrates the percentage distribution of various applications of Laser Surface Treatment. Industries such as Automotive and Aerospace take a significant share, showcasing the importance of this technology in enhancing product performance and durability.

Laser surface treatment technology operates on the principle of using focused laser energy to modify the surface of materials. This process can enhance properties such as hardness, wear resistance, and corrosion resistance. By precisely controlling the laser parameters, different effects can be achieved, such as melting, alloying, or even surface cleaning. The intensity and duration of laser exposure determine the extent of the change in properties.

In practice, achieving the desired outcome can be challenging. Not every material reacts the same way to laser treatment. Factors like surface contamination or uneven surfaces can lead to inconsistencies. It's crucial to analyze the material properties beforehand. Testing is often necessary to refine the process parameters, ensuring optimal results.

Observing these imperfections can provide insights into how improvements can be made in future applications. Continual learning is key in laser surface treatment technology. Each project offers unique challenges, requiring adaptation and innovation.

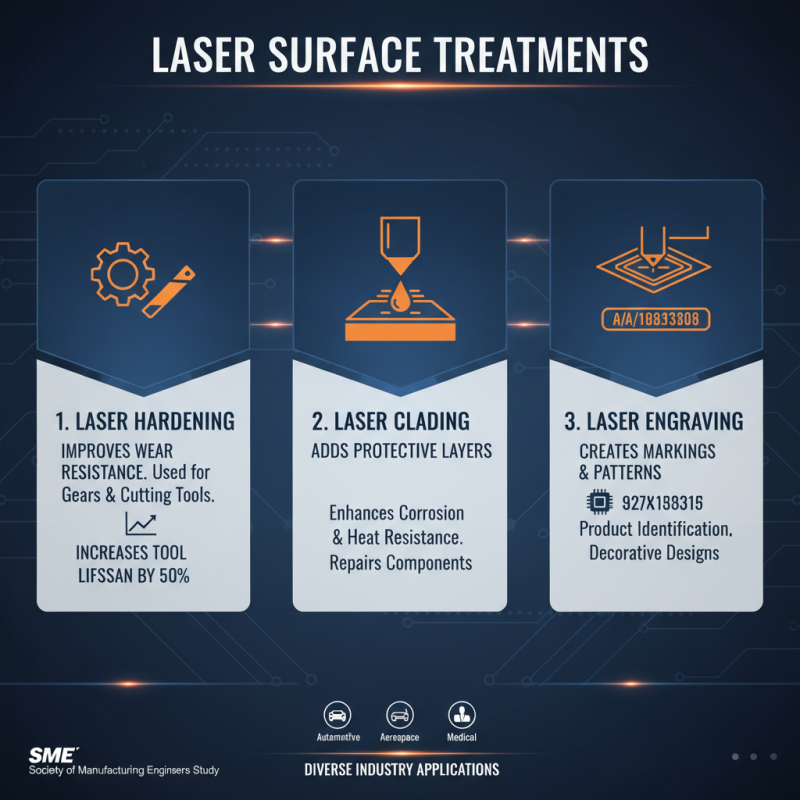

Laser surface treatments encompass various methods aimed at enhancing the properties of materials. Techniques include laser hardening, cladding, and engraving. Each method serves a specific purpose and finds application across diverse industries. For example, laser hardening improves wear resistance. It's often used in manufacturing gears and cutting tools. A study by the Society of Manufacturing Engineers indicates that laser hardening can increase the lifespan of tools by up to 50%.

Laser cladding involves adding material to surfaces. This is particularly valuable in repairs. It restores worn parts, making them as good as new. A report from the International Journal of Advanced Manufacturing Technology states that laser cladding can significantly reduce production costs by extending the life of machinery. It is extensively applied in aerospace and automotive industries, marking a shift towards sustainability.

Tips: Always consider the material's compatibility with laser treatment. Testing can prevent costly errors. Monitor parameters closely during the process. Even minor fluctuations can impact results. The technology is powerful but needs careful execution. Regular maintenance of laser systems can enhance their performance and longevity. Understanding the nuances of each treatment type is crucial for effective application.

Laser surface treatment has become a popular technology in material processing. It modifies material properties through focused laser beams. Various reports indicate that up to 90% of treated materials show enhanced hardness and wear resistance. This is crucial for industries like aerospace and automotive, where durability is key.

One major benefit is improved fatigue resistance. Laser treatment can alter the microstructure of metals, making them more robust under stress. Research suggests that components treated with laser technology have a lifespan increase of 30-50%. This longevity can significantly reduce maintenance costs and downtime for manufacturers.

Tips: Consistent laser settings are vital for optimal results. Experiment with different power levels to observe changes. Regularly check the uniformity of treatment to avoid inconsistencies. This method does require careful monitoring, as too much heat can lead to warping, which might undermine the benefits of the process.

Laser surface treatment is evolving rapidly. Techniques like laser hardening and polishing are becoming commonplace in various industries. These methods enhance durability and reduce wear on metal parts. However, not all applications may see the expected improvements. It's crucial to assess individual needs before implementation.

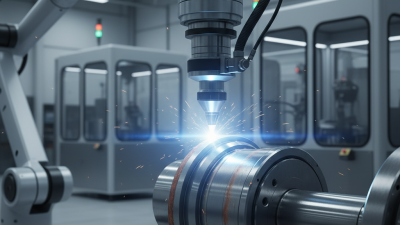

Future trends indicate a shift toward automation in laser treatment processes. Robotics will likely play an essential role in operating laser equipment. This could streamline production and improve consistency. However, relying heavily on automation may create challenges in quality control.

Tips: Always test materials before full-scale use. Small-scale trials can help identify potential issues. Staying informed about new laser technologies is vital. Regular training for staff will also ensure optimal results. Adaptability will remain key as techniques continue to change and improve.

| Technique | Material Suitability | Applications | Benefits | Future Trends |

|---|---|---|---|---|

| Laser Hardening | Steel, Aluminum | Automotive, Aerospace | Increased wear resistance, improved performance | Automation and AI integration |

| Laser Coating | Metals, Plastics | Energy, Electronics | Corrosion resistance, thermal protection | Development of novel coatings |

| Laser Ablation | Glass, Ceramics | Medical devices, Electronics | Precision removal, minimal thermal impact | Enhanced precision and control |

| Laser Texturing | Acrylics, Metals | Consumer products, Automotive | Improved aesthetics, functionality | 3D texturing techniques |

| Laser Welding | Metals, Plastics | Manufacturing, Repair | Strong bonds, reduced heat affected zone | Automation and integration with robotics |