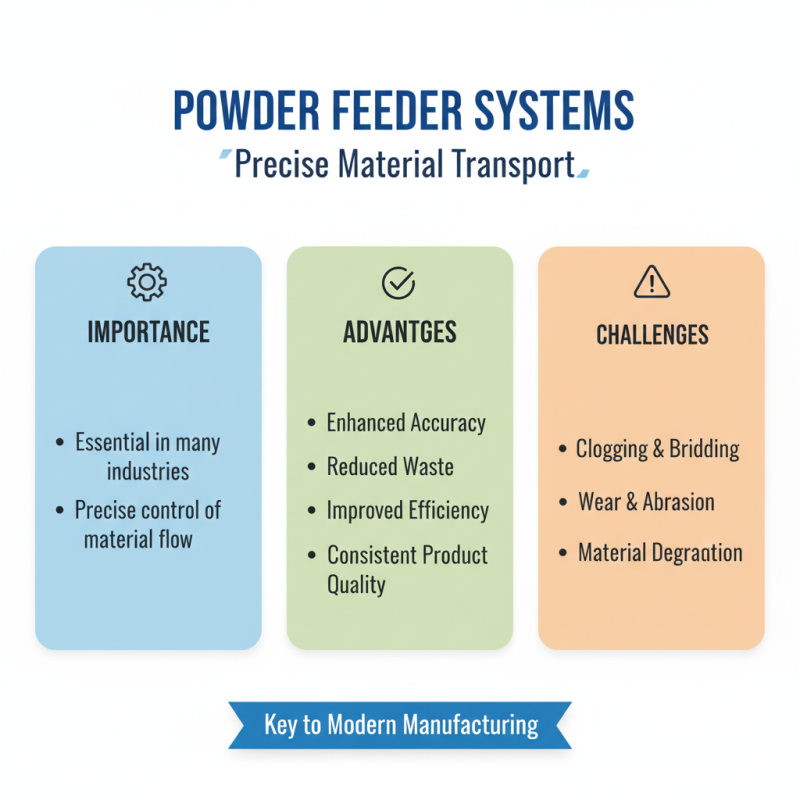

A Powder Feeder System is an essential component in many industries. It facilitates the accurate dosing and delivery of powdered materials. These systems are widely used in sectors such as pharmaceuticals, food processing, and plastics manufacturing.

Understanding how a Powder Feeder System operates is crucial for optimizing production processes. It typically involves a hopper for storage and a feeder mechanism to dispense powders consistently. The system can be automated or manually operated, depending on specific requirements.

While Powder Feeder Systems offer numerous benefits, there are areas for improvement. Calibration might be challenging, leading to inconsistencies. Additionally, the dust generated during operation can pose health risks. These aspects require careful consideration to enhance efficiency and safety.

A powder feeder system is a device designed for precise dispensing of powder materials. These systems are crucial in various industries, including pharmaceuticals, food processing, and materials engineering. According to a report from the Global Powder Coating Market, the demand for efficient powder handling solutions has increased significantly. This growth is driven by the need for accuracy in formulation and consistency in production.

These systems work by precisely controlling the flow of powder through various mechanisms such as augers or vibration feeders. They ensure uniformity in the mixing process, which is essential in applications like additive manufacturing. Reports indicate that a consistent powder feed can enhance the quality of the final product. However, achieving this can be challenging. Variations in particle size and moisture content often lead to feeding issues.

The purpose of a powder feeder system extends beyond mere dispensing. It plays a vital role in maintaining production efficiency. Mishandling or inaccurate feeding can lead to defective products, increased waste, and ultimately higher costs. The industry continues to face challenges in optimizing these systems, as factors like environmental conditions can affect performance. There is always room for improvement in achieving flawless powder delivery.

A powder feeder system is essential for accurately delivering powdered materials in various industries. It consists of key components that work together to ensure efficient feeding. The main components include a powder hopper, feeder mechanism, control system, and delivery tube.

The powder hopper holds the material, maintaining a steady supply. It's crucial to design this component efficiently; otherwise, you may face material flow issues. The feeder mechanism can be a screw feeder or a vibratory feeder. Each type has its advantages and challenges. Proper calibration is critical for consistent delivery.

The control system monitors and adjusts the feed rate based on process needs. An effective control system can enhance material usage. A poorly calibrated system can lead to wastage and inconsistencies in product quality.

Tips: Regularly check for clogs in the delivery system. Keep records of feed rates and adjust as necessary. Maintenance is key. Remember, not all powders behave the same; properties can vary widely. Understanding these differences can improve your process significantly.

A powder feeder system plays a crucial role in various industries such as pharmaceuticals, food processing, and metal additive manufacturing. The principle of operation in powder feeding hinges on precise control and distribution of powder materials. It ensures the right amount of material is fed into processes like mixing, extrusion, and coating. Depending on the application, a feeder can operate continuously or in batches, which affects the efficiency of the complete system.

Typically, a powder feeder relies on mechanisms like vibratory feeders or screw conveyors to transport the powder. Studies show that approximately 30% of feeding issues stem from poor flowability of powdered materials. This problem can be exacerbated by factors such as particle size, shape, and moisture content. Adjusting these parameters can improve flow and reduce downtime due to blockages or inconsistencies. Ensuring the powder is adequately conditioned can lead to operational efficiencies of up to 25% in some scenarios.

However, practical challenges often arise in managing different powders. Each material has unique characteristics requiring specific feeder designs. For instance, some powders may clump together, making even distribution tough. Observations from industry reports indicate that as much as 40% of manufacturers face difficulties with powder feeding. Therefore, ongoing refinement in feeding technology is necessary for enhanced reliability and performance.

Powder feeder systems play a crucial role in many industries. They are primarily used for precise powder delivery in processes like additive manufacturing, pharmaceuticals, and food production.

In additive manufacturing, these systems ensure consistent material flow. This leads to better quality and performance of the final product.

In the pharmaceutical industry, powder feeders help in the formulation of medicines. Accurate dosing is essential here. Even a small deviation in powder quantity can affect efficacy. It’s critical for compliance and 安全.

In food production, powder feeders are used to add ingredients uniformly. This promotes consistency in taste and texture across batches.

Despite their advantages, challenges remain. Companies must regularly calibrate equipment to maintain accuracy. Small clogs can disrupt the product flow. Operators require training to handle these systems effectively. Observing these pitfalls can lead to improved processes.

Powder feeder systems are essential in many industries. They allow for precise control over powder material transport. These systems have several advantages but are not without challenges.

One of the main benefits is accuracy. Powder feeder systems can deliver exact amounts of material. This can improve product quality. Less waste is produced, which is financially beneficial. Operators appreciate the consistency these systems provide. However, they need regular maintenance to avoid clogs.

Challenges arise when it comes to material variability. Different powders exhibit varying flow characteristics. This can affect the feeding process. Operators must be aware of how environmental factors can impact performance. Maintaining an optimal feed rate is crucial.

Tip: Regularly monitor powder types used. This can aid in identifying potential flow issues early.

Another tip: Keep the system clean. Dust buildup can create problems over time.

Routine checks can save time and costs in the long run. Operators should not overlook the need for adjustments. Understanding and addressing these challenges can maximize the system’s potential.