Laser repair techniques are transforming restoration solutions across various industries. According to a recent report by MarketsandMarkets, the global laser technology market is projected to reach $15.09 billion by 2026, driven largely by advancements in laser repair methods. This surge reflects the undeniable effectiveness of laser repair in restoration projects, particularly in manufacturing and automotive sectors.

Laser repair offers precision and efficiency that traditional methods struggle to match. For example, it minimizes material waste and reduces overall repair time. Yet, challenges remain. Many professionals still lack comprehensive training in these techniques. This gap can lead to inconsistent results, calling for more education and experience in the application of laser technology.

Understanding the ten best laser repair techniques is crucial for those seeking effective restoration solutions. Each technique not only demonstrates varying levels of effectiveness but also highlights the need for careful consideration and ongoing innovation within the industry. As we explore these techniques, it’s important to note that continuous improvement and reflection on outcomes are necessary to elevate laser repair practices further.

Laser repair techniques are gaining popularity in restoration projects. They offer precision and efficiency. It's fascinating how lasers can restore damaged surfaces without altering surrounding materials. For instance, they can rejuvenate artwork by precisely targeting specific areas. This minimizes collateral damage, allowing for focused restoration.

However, not every technique is perfect. Some projects require extensive planning. The operator's skill level can impact the outcome significantly. There are times when lasers may not reach deep-seated damage. In these cases, alternative methods might be more effective. Each restoration project should be evaluated meticulously to determine the best approach.

Another challenge lies in the cost and accessibility of equipment. High-quality laser systems can be expensive and require proper training. This can lead to a reliance on less experienced technicians, which may compromise quality. Restoration projects often get delayed due to these hurdles. Balancing quality, cost, and time is critical for success in laser restoration techniques.

| Technique | Description | Applications | Advantages | Limitations |

|---|---|---|---|---|

| Fiber Laser Repair | Uses fiber optics to deliver laser energy for precise cutting and welding. | Metal fabrication, electronics repair. | High precision, minimal thermal distortion. | Limited to materials compatible with fiber lasers. |

| CO2 Laser Repair | Utilizes CO2 gas to generate a high-intensity beam for cutting and engraving. | Plastic, wood, and acrylic materials. | Versatile and effective for non-metal materials. | Lower efficiency on metals compared to fiber lasers. |

| Nd:YAG Laser Repair | Employs Nd:YAG crystals to produce a focused beam for welding and drilling. | Aerospace components, medical devices. | Deep penetration and high power. | Can be costly and require significant maintenance. |

| Laser Cleaning | Uses laser energy to remove contaminants from surfaces. | Restoration of historical artifacts, industrial machinery. | Eco-friendly, precise, and minimal wear on substrates. | May not be effective on heavy corrosion or thick paint. |

| Laser Etching | Involves using a laser to engrave designs on materials. | Signage, personalized gifts, jewelry. | High detail and customization options. | Limited to surface-level applications. |

| Laser Welding | Joins materials by melting them with laser energy. | Automotive, aerospace, and manufacturing. | Strong joins, fast processing speeds. | Requires precise alignment and setup. |

| Laser Marking | Creates permanent marks on surfaces using laser pulses. | Product identification, barcodes. | Permanent and high contrast markings. | Depth of mark is often limited. |

| 3D Laser Scanning | Captures detailed 3D data of objects for analysis or replication. | Heritage preservation, reverse engineering. | Highly accurate and detailed models. | Can be expensive and requires specialized equipment. |

| Laser Resurfacing | Improves surface finish by removing layers of material. | Automotive and aerospace component restoration. | Enhances surface quality and reduces defects. | Time-consuming for extensive repairs. |

Laser damage can occur in various forms, such as surface abrasions or deeper structural defects. Identifying these common issues is crucial for effective restoration. According to industry reports, about 30% of laser users face repair needs due to mishandling or equipment aging. Regular maintenance can prevent this.

One common type of laser damage is lens corrosion. Corrosion can reduce laser efficiency significantly. Users should inspect lenses regularly and replace them at the first sign of wear. Cleaning them with appropriate solvents can help, but it might not always be enough. If the damage is severe, lens replacement may be necessary.

Tip: Implement a routine inspection schedule for your laser equipment. This way, you can catch potential issues early.

Another frequent problem is misalignment of optical components. Even slight misalignments can lead to reduced performance. Users are advised to check alignment regularly, especially after transporting equipment. Additionally, ensure that all components are securely fastened. If you notice performance issues, recalibration might be needed.

Tip: After calibration, run a test pattern to confirm alignment. This ensures everything is functioning correctly.

While it's vital to maintain equipment, mistakes can happen. Being mindful of handling practices and understanding common issues can lead to more effective laser restoration solutions.

Laser repair techniques are becoming increasingly important in various industries. The process starts with accurately assessing the damage. Using laser technology allows for precise targeting, minimizing collateral damage to surrounding areas. This is crucial, especially in delicate repairs. According to industry reports, effective laser repair can enhance restoration speed by up to 40%, significantly improving workflow efficiency.

Next, the selection of the appropriate laser type can greatly influence outcomes. For instance, fiber lasers are known for their effectiveness in metal repair. One study notes that using the right wavelength can reduce defect rates by nearly 30%. This is vital when working on intricate components with tight tolerances. However, not all technicians are adequately trained in advanced laser techniques, which can lead to inconsistent results.

Following the initial repair, detailed inspections and follow-ups are essential. Not every repair achieves perfect results on the first attempt. Imperfections may require additional adjustments or refinements. An internal review may reveal areas for improvement in technique application. Data shows that continuous training on the latest technologies improves overall repair quality. Focusing on these aspects leads to better outcomes and higher client satisfaction rates.

This chart displays the effectiveness of different laser repair techniques based on customer satisfaction ratings. Each technique's effectiveness is rated on a scale from 1 to 10, with 10 being the most effective.

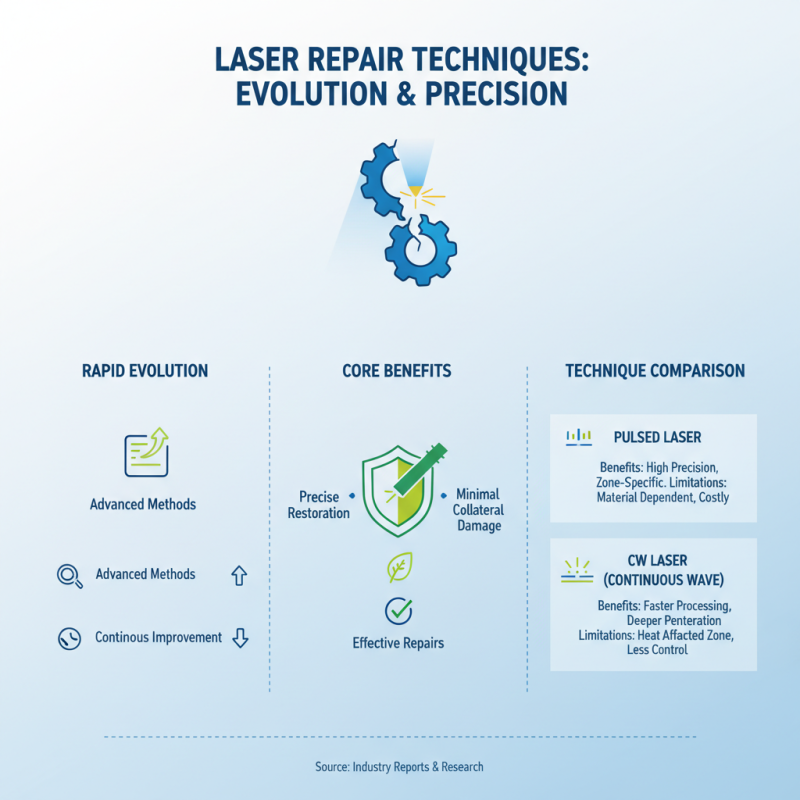

Laser repair techniques are rapidly evolving. They offer precise restoration solutions across various fields. These advanced methods ensure effective repairs while minimizing damage to surrounding areas. Comparing techniques reveals distinct benefits and limitations.

One technique relies on short, intense pulses of laser energy. This can effectively restore delicate components. However, it requires careful calibration. Another method utilizes lower energy levels, allowing for more extensive applications. Yet, it may take longer to achieve desired results.

In addition, some techniques focus on thermal effects, while others emphasize photochemical reactions. The choice often depends on specific materials and the extent of damage. Overall, exploring these differences allows for better-informed decisions. As technologies advance, continuous evaluation of methodologies is essential. The world of laser repair is complex and ever-changing.

Selecting the right equipment for laser repair applications is crucial for optimal results. Industry data shows that the efficiency of laser repair processes increases by up to 30% with appropriate tools. Factors such as power output, wavelength, and beam quality greatly impact the effectiveness of repairs.

When choosing equipment, it’s vital to consider the material you are working with. Metals, plastics, and ceramics require different settings and laser types. For instance, a study indicated that fiber lasers perform exceptionally well on metals, whereas CO2 lasers are better for plastics. A mismatch in equipment can lead to ineffective repairs and wasted resources.

Additionally, training and familiarity with the equipment can significantly influence outcomes. Reports suggest that 45% of operators feel underqualified for specialized repairs. Investing in skilled personnel and the right technology is essential. Reflecting on past projects can reveal areas for improvement and guide future equipment choices.