In the rapidly evolving landscape of industrial applications, the integration of advanced technologies has become essential for maintaining competitiveness and efficiency. Among these advancements, Laser Heads stand out as transformative tools that are reshaping various manufacturing processes. According to a report by the International Data Corporation (IDC), the global market for laser technology in industrial applications is projected to reach $18 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 7%. This growth emphasizes not just the rising demand for precision and speed in production, but also the evolving capabilities of Laser Heads that enhance these qualities.

The versatility of Laser Heads encompasses a range of functions, from cutting and engraving to welding and marking. Their ability to produce high-quality outputs with minimal waste aligns with the current industry push towards sustainable practices, as highlighted in a McKinsey report that indicates companies adopting laser technologies save up to 30% in material costs. Moreover, innovations in laser systems, such as fiber and CO2 laser technologies, have saturated the market, offering solutions that meet the diverse needs of industries like automotive, aerospace, and electronics. This article explores the "Top 10" advancements in Laser Heads that are paving the way for a future defined by precision, efficiency, and reliability in industrial applications.

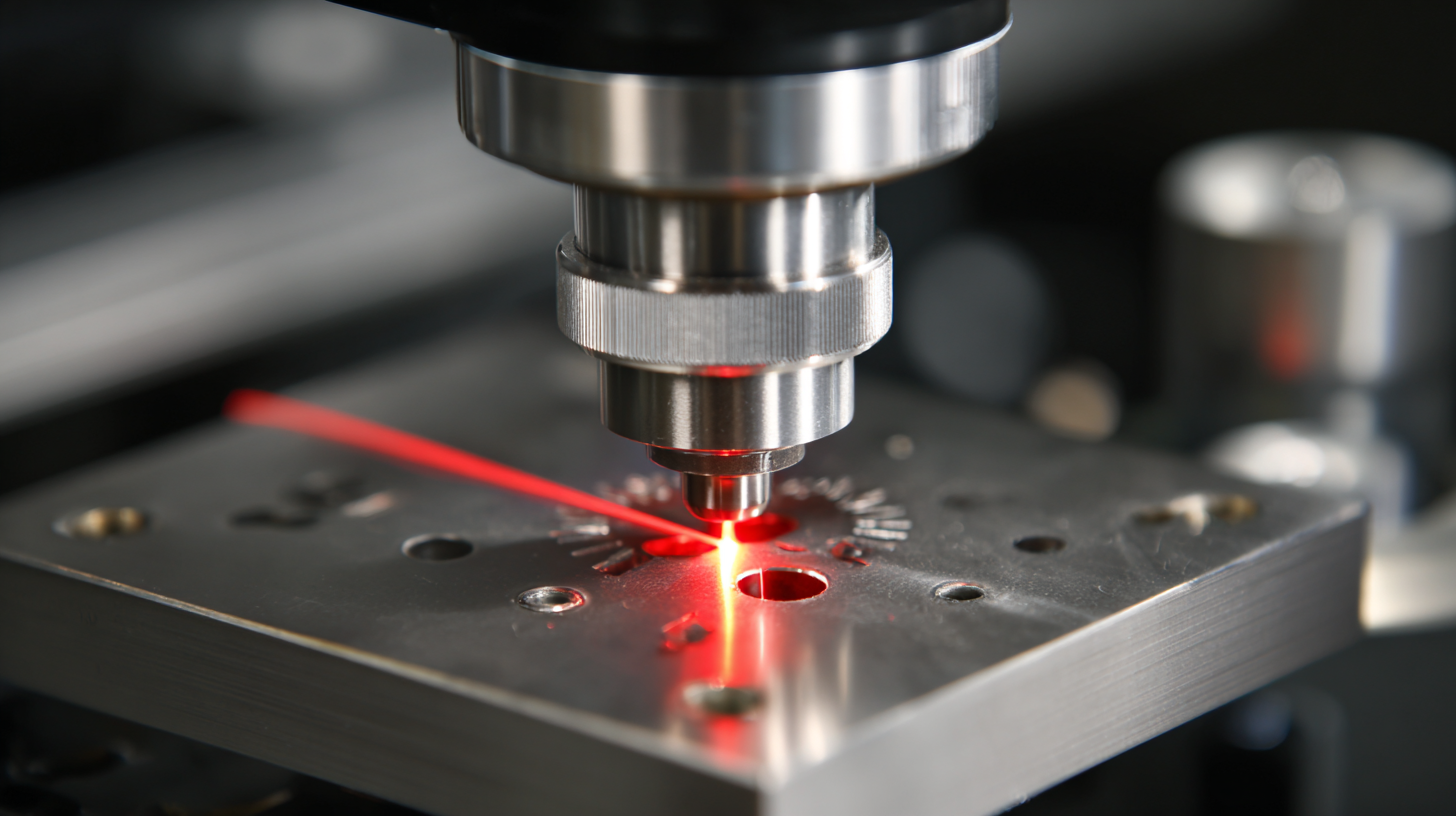

The rise of laser head technology in precision manufacturing industries marks a significant advancement in production capabilities, driven by innovations that enhance accuracy and efficiency. With a growing emphasis on precision, new developments such as the Nozzle Visual Aligner (NVA) promise to address long-standing calibration challenges in laser cutting by providing high-precision alignment between the laser and nozzle, thus ensuring optimal performance in various applications. This breakthrough not only bolsters manufacturing precision but also opens avenues for high-quality outcomes in sectors such as electronics and automotive.

Moreover, the integration of AI-powered laser technologies is redefining agricultural practices by introducing precision weeding robots that minimize herbicide use, demonstrating the versatility and impact of laser applications beyond traditional manufacturing. As the laser processing market expands to an estimated $42.73 billion by 2030, it underscores the critical role that innovative laser head technology plays in shaping future industrial landscapes, driving growth and enhancing operational excellence across diverse sectors.

In the realm of industrial applications, laser heads are revolutionizing the cutting process by offering significant advantages over traditional cutting tools. One of the foremost benefits is precision. Laser heads can achieve intricate designs and cuts with exceptional accuracy, minimizing material waste and reducing the need for extensive post-processing. This level of precision allows manufacturers to produce complex parts that would be nearly impossible to create using conventional methods.

Additionally, laser cutting systems provide enhanced speed and efficiency. Unlike traditional tools that may require multiple passes or adjustments, laser heads can swiftly cut through various materials, including metals, plastics, and composites, with minimal downtime. This capability not only accelerates production but also increases overall throughput, positively impacting operational costs. The versatility of laser technology further empowers industries to adapt to changing demands, allowing for quick transitions between different materials and designs without the long lead times associated with traditional tooling. As technology continues to evolve, laser heads are poised to lead the way in making industrial processes more efficient and precise.

The industrial landscape is rapidly evolving, with laser cutting systems at the forefront of technological advancement. According to market forecasts, China's laser equipment sector is expected to generate significant sales, reaching 91 billion RMB in 2024, marking a substantial growth from previous years. Specifically, the market for laser cutting equipment alone is projected to hit 36.85 billion RMB, underscoring a robust demand for precision manufacturing tools that are integral to various sectors.

As we look towards 2025, the global laser market is anticipated to expand impressively, with estimates indicating an increase from 19.8 billion USD in 2024 to 25.9 billion USD by 2033, reflecting a compound annual growth rate (CAGR) of 3%. Furthermore, the fiber laser segment is set to experience remarkable growth, with projections suggesting an increase from 4.63 billion USD in 2025 to 10.75 billion USD by 2032, demonstrating a CAGR of 12.8%. This momentum indicates not only a heightened adoption of laser technologies but also a drive towards innovative solutions in sectors like manufacturing and telecommunications, promising a bright future for laser heads in industrial applications.

| Year | Market Size (Million USD) | Growth Rate (%) | Key Industries | Technological Advancements |

|---|---|---|---|---|

| 2021 | 1,500 | 5.0 | Automotive, Aerospace | Fiber Laser Technology |

| 2022 | 1,750 | 7.5 | Electronics, Medical | High-Power Lasers |

| 2023 | 1,900 | 8.6 | Construction, Signage | Automation Integration |

| 2024 | 2,100 | 10.5 | Textiles, Packaging | 3D Laser Printing |

| 2025 | 2,500 | 12.5 | Aerospace, Energy | AI in Laser Technology |

The future of laser heads in industrial applications is increasingly tied to their impact on production efficiency and cost reduction. As industries embrace advanced laser technologies, the ability of high-power laser systems to enhance precision in various applications—ranging from aerospace to automotive—becomes paramount. These advancements not only fine-tune manufacturing processes but also drastically lower operational costs by minimizing material waste and reducing cycle times. In sectors like wind energy, for instance, enhanced welding quality for turbine components directly correlates with increased reliability and longevity, driving down maintenance costs over time.

As manufacturers transition towards digital transformation and personalized processing, the demand for precise laser cutting services, particularly in niche markets, has never been more pronounced. The rise of customized solutions in tooling and equipment demands requires an ongoing commitment to precision laser technologies, which can significantly influence product quality and production efficiency. This evolution signifies that companies equipped with state-of-the-art laser systems are not just keeping pace with market demands but are positioned to lead—capitalizing on the growing need for high precision to optimize production workflows while achieving substantial cost savings.

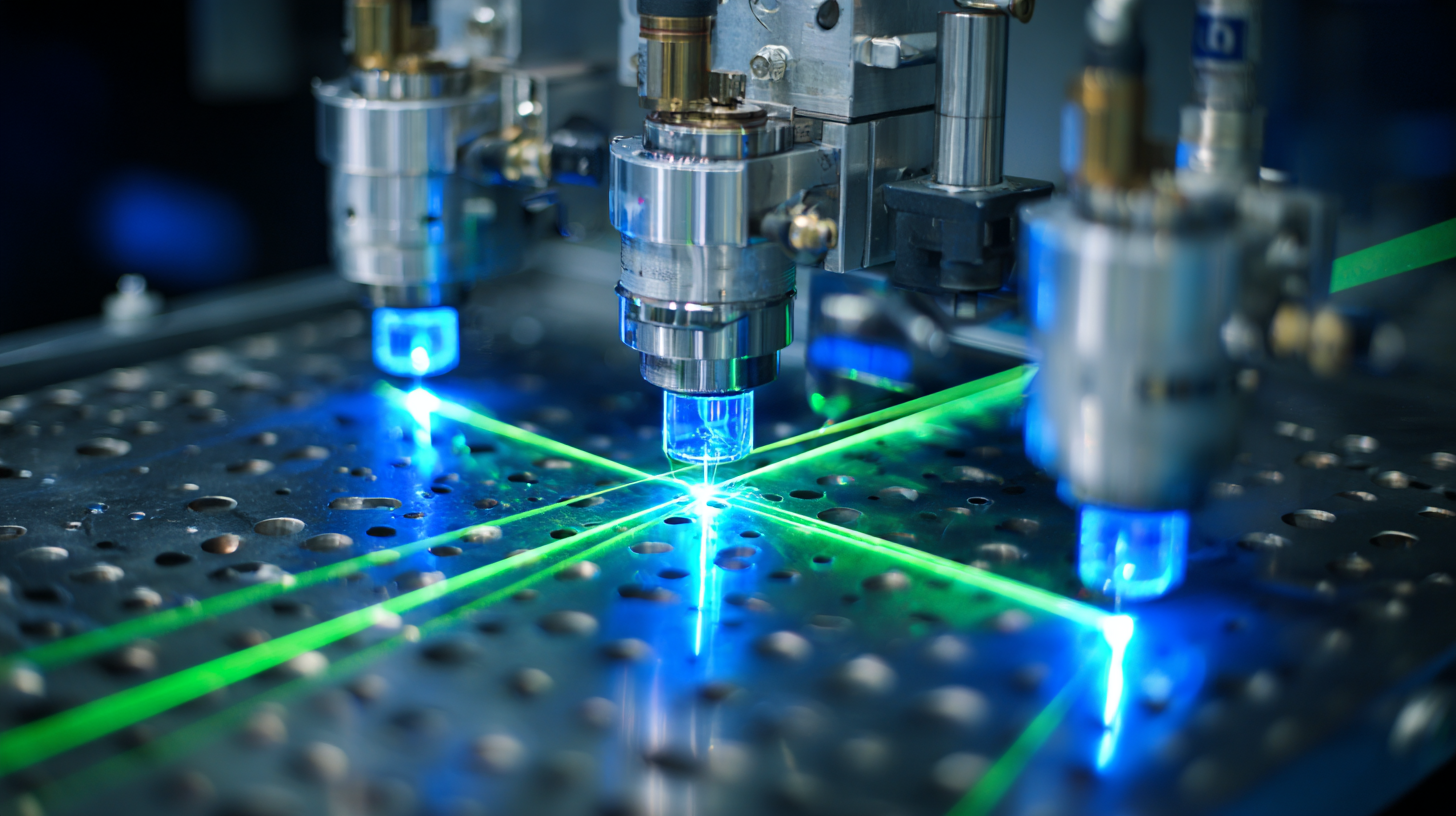

The future of laser head technology is poised for significant transformation, driven by advancements in design and functionality. As industries evolve, the integration of cutting-edge technology, such as CNC punch presses and laser cutters, is becoming essential. Recent reports from leading additive manufacturing companies indicate that ongoing innovations in laser technology are enhancing precision and efficiency, positioning laser cutting as a preferred method in production processes. For instance, a recent survey highlighted that 72% of industry leaders believe that advanced laser systems will play a critical role in achieving higher productivity levels by 2025.

Moreover, as manufacturing demands increase, the capability of laser heads to deliver customizable solutions is becoming a key competitive differentiator. The latest innovations focus on optimizing laser beam quality and integrating smart control systems, which not only improve accuracy but also reduce operational costs. According to market analysis, the global laser cutting market is projected to grow by over 8% annually, driving further investment in sophisticated laser head technology. This trend reflects a broader shift towards automation and smart technologies, where the functionality of laser heads will continue to expand, allowing for increased capabilities across various industrial applications.