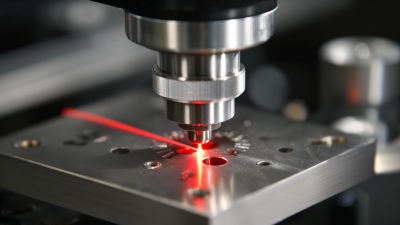

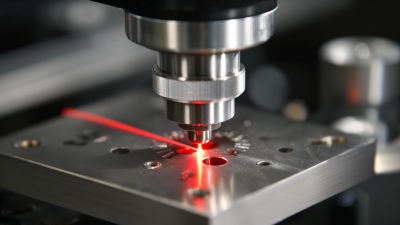

Unlocking Precision: The Future of Laser Heads in Industrial Applications

In the rapidly evolving landscape of industrial applications, the integration of advanced technologies has become essential for maintaining competitiveness and efficiency. Among these advancements, Laser Heads stand out as transformative tools that are reshaping various manufacturing processes. According to a report by the International Data Corporation (IDC), the global market for laser technology in industrial applications is projected to reach $18 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 7%. This growth emphasizes not just the rising demand for precision and speed in production, but also the evolving capabilities of Laser Heads that enhance these qualities.

The versatility of Laser Heads encompasses a range of functions, from cutting and engraving to welding and marking. Their ability to produce high-quality outputs with minimal waste aligns with the current industry push towards sustainable practices, as highlighted in a McKinsey report that indicates companies adopting laser technologies save up to 30% in material costs. Moreover, innovations in laser systems, such as fiber and CO2 laser technologies, have saturated the market, offering solutions that meet the diverse needs of industries like automotive, aerospace, and electronics. This article explores the "Top 10" advancements in Laser Heads that are paving the way for a future defined by precision, efficiency, and reliability in industrial applications.

Read more »

By:Ethan - November 22, 2025

By:Ethan - November 22, 2025

By:Ethan - November 20, 2025

By:Ethan - November 20, 2025

By:Ethan - November 19, 2025

By:Ethan - November 19, 2025